Internal benchmarking for safety standards and accident rates have been performed for many years, comparing sites within a business, and presenting the results in a corporate league table. This identifies the worst and best-performing sites in terms of HSE and can help with sharing best practices from within the business. The goal is for all sites to embark on a journey of continuous improvement with more emphasis usually made on the worst-performing sites. Targets are set, and plans are put in place for continuous improvement.

Whilst working for ICI in the UK in the late 1980s, we were often presented with corporate safety statistics showing how we internally compared but also how we compared as a corporate entity with other similar businesses. We were usually compared against companies like DuPont who had made some massive gains in health and safety improvement. There was always a debate, that we were not always comparing apples with apples.

What about Asset Management?

- Are you maintaining and operating your assets without really knowing where you sit in terms of best/good practice?

- Are some of your sites performing better than others?

- Are you sharing best/good practices internally and learning from each other?

Asset Management is another key area in which an organisation can start to benchmark, not just against external companies but internally across their own sites.

It can be argued that some businesses are not able to benchmark internally due to possible differences such as the installed base, raw materials, environmental conditions etc but if the organisation as installed a number of standards with which Asset Management needs to be followed, then these can be benchmarked from site to site.

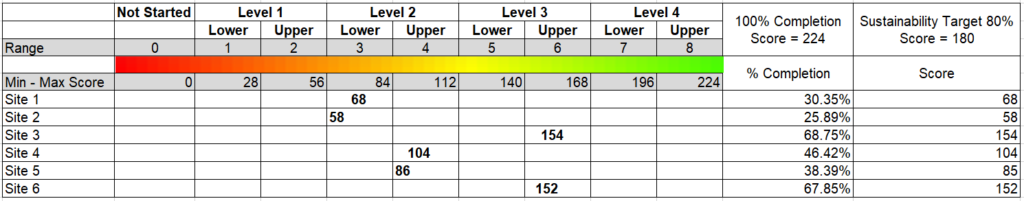

Pro-Reliability Solutions were recently invited to visit six company sites and carry out an independent benchmarking study against several corporate internal standards. The goal was to establish the status of each site and identify a path forward for each facility to follow with a sustainability target score.

Whilst Pro-Reliability Solutions have their own benchmarking self-assessment tool, we met with the company and reviewed an existing internal scoring tool that they had previously used at the start of their Asset Management journey. It was agreed the categories and the scoring mechanism required updating to allow for more granularity in the range of scores. The sites were then visited, and plant tours and interviews took place to allow the population of the benchmarking tool.

Categories

The study covered several different categories which included the following:

| Reliability Leadership | Defect Elimination |

| Maintenance Vision, Mission and Goals | Planning and Scheduling |

| Performance Measurement | Training and Development |

| Zero Loss Philosophy | Lubrication |

| Daily Management | Autonomous Maintenance |

| Legal Compliance | Spare Part Management |

| Criticality Ranking | Early Equipment Management |

| Engineering Organisation | Maintenance Procedures |

Results

With each site complete, the results were compiled into individual site A3 Status reports which highlighted the following:

- Who

- When

- 12 Key Observations

- Site Overall Score

Improvement Observations and Recommendations

Site Scores

Each site was presented with their results and a plan put in place to help reach the sustainability target.

Summary

The site visits certainly produced some interesting conversations and results, pockets of excellence existed across all sites and everybody were engaged and aiming to do the right thing in line with company objectives.

Testimonial

This was a well-executed exercise led by Pro-Reliability Solutions. It provided us with an independent, clear, and precise output which will now be used as the foundations for our continuous improvement journey. We would not hesitate in using Pro-Reliability Solutions to perform this activity again in the future.

- Asset Manager (Group)

Further Information

If you are interested in performing a Reliability Maturity Self-Assessment at your facility or would like to develop a roadmap for your Reliability future, then please get in touch.